Truck and Bus Radial Tyres – The Basics

Size, Load and Speed

Truck and bus radial (TBR) tyres present an array of options that go far beyond tyres for recreational vehicles. However, the basics are the same.

Every tyre has a specific size, a maximum load capacity and a maximum speed. These basic descriptions are shown on every tyre. As a fleet manager we’re sure that you already know these basics – consider reading this article for background reading on tyre basics.

Ply Rating and Load Range

In addition, every TBR tyre also has a ply rating, a term also known as “load range.” Ply ratings do not correspond to the number of actual ply layers inside the tyre, but the equivalent strength when compared to early bias ply tyres. The higher the ply rating or load range, the higher the strength of the tyres and greater its load carrying capacity.

Modern technology allows manufacturers like Longmarch to engineer greater tyre strength and capacity without adding extra nylon layers to the tyre. This is achieved by adding reinforced steel layers that increase the ply rating.

Vehicle Applications and Tread Patterns

Every wheel has a different role on a truck or heavy vehicle. TBR tyres are manufactured to meet specific functions. Their patterns and composition are designed to meet specific needs, also known as vehicle applications.

In general there are two sides to tread design. One is fuel efficiency, the other is traction. All Longmarch tyres meet these two requirements. Certain patterns are a blend of both, however, different tread patterns work best on different wheels.

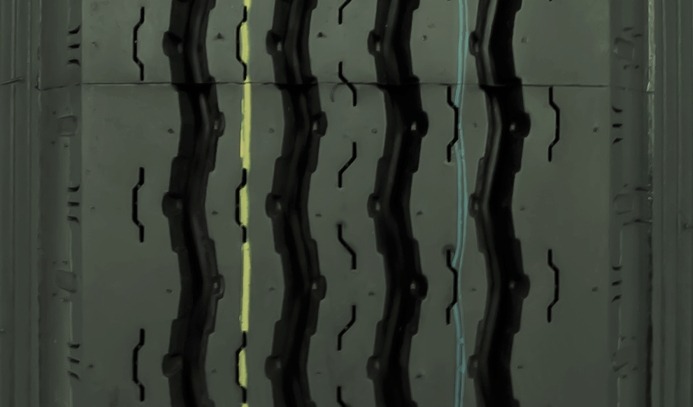

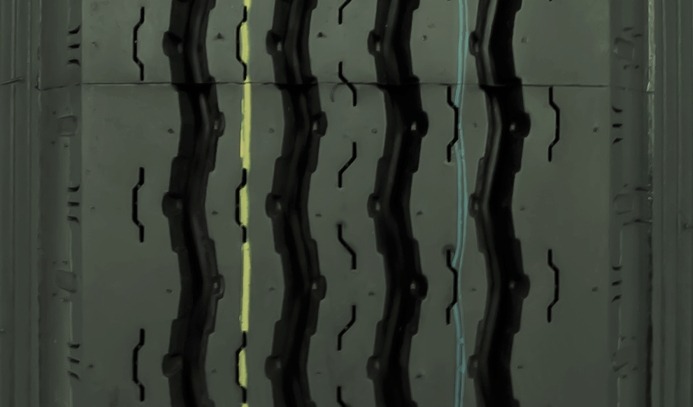

Steer – Steer tyres are the most important tyres on your fleet’s vehicles. They are designed to perform their best when out in the front. These typically have parallel grooves (a ribbed design) offering high cornering ability. They have low rolling resistance and low noise. The parallel groove design allows for greater control and manoeuvrability.

Drive – Drive tyres need to work incredibly hard. They must grip all road surfaces, transferring power and traction to the vehicle. These tyres usually have a block design, with lateral and perpendicular grooves within the tread. They need an increased tread depth, to counter the scrubbing and spinning that occurs when power is transmitted through the drive axle.

Trailer – Trailer tyres need to be all rounders. They must withstand strong braking and lateral forces, as well as varying roads. Reinforced sidewalls are essential (a key feature of an All-Steel design) as they protect the tyre from curb damage. Although these tyres typically have parallel grooves they are constructed to be highly flexible and durable.

All Position – As their name suggests, all position tyres can perform in all positions. Still, with larger fleets and larger trucks, choosing specialised steer and drive tyres will provide performance and efficiency savings over time. All position tyres are more common on light trucks and buses, where there is less variation in the demands for each wheel.

Road Conditions and Tread Profiles

Let’s recap: when buying tyres for a fleet you need to know the load that will be carried, where the tyre will be used on the vehicle, and the size of the wheel.

The next key consideration is where your vehicles drive. Every type of road brings its own challenges and opportunities. When buying tyres you must ensure that the tyres can perform over a sustained period of time, as well as assisting in improving the vehicle’s mileage. So it’s essential to choose tyres based on the road conditions as well.

Highway – Tyres that spend most of their time on the highway must be formulated to maximise mileage and efficiency. These tyres are designed to minimise rolling resistance and help ensure regular wear. While these considerations are essential to every tyre, it’s on a highway that they are most keenly felt. Longmarch highway tyres are known for their enhanced longevity. Highway tyres can also be known as long distance tyres.

City – Regional tyres need the flexibility to work well in all on road conditions. These are for vehicles that use highways, but also spend a significant amount of time on smaller roads, at lower speed. These tyres withstand braking and lateral forces that are both innumerable and inconsistent. Therefore they must provide greater traction and strength, while still ensuring long-term fuel efficiency.

On/Off Road – Some vehicles must perform on every type of road. Extra traction is required when going off road, but can give the tyre too much traction and impact fuel economy when on the asphalt. Longmarch on/off road tyres provide the balance that is required. They have increased tread depth and an All-Steel design that provides the power needed in off-road conditions.

Off Road – Off road tyres need serious traction. They are the workhorses of your fleet, strong, durable, and ready for all situations. Off road tyres have enhanced tread profiles and tend to have a block design that can be used in all wheel positions, not just on the drive position. However, note that these larger tyres will have a lower speed rating and are not especially efficient when on the road. So only choose off road tyres when the vehicle spends most of its time off road.

Structure and Compound

TBR tyres are placed under intense pressure. Think of riding up curbs, braking intensely with extra heavy loads, exceeding 100,000 in a year, and the demands brought by going off road. Then add on the challenges of driving in the Middle East, particularly the desert and the heat.

Most tyres only use steel cords in the tread areas. This leaves the sidewalls vulnerable. An All-Steel tyre has additional protection for the sidewall casing, as well as providing a higher weight carrying capacity. Radial steel plies also transmit load and braking forces between the tyre tread and the wheel. Again, an All-Steel design proves stronger and more durable.

Other considerations include the rubber that is being used, and whether it has a thick anti-aging rubber covering. Puncture resistance is essential to the compound if your fleet is based in the Middle East. All-Steel technology also enables tyres to be re-grooved and retreaded, therefore extending their life.

Certifications – Choosing the Right Tyres with GSO Labels

When buying any TBR tyre it’s essential to check that it conforms to international quality standards. This is obviously important for safety reasons and may have legal implications for fleets as well. Fitting substandard non-certified tyres can lead to serious issues for a fleet manager if a vehicle is in an accident.

Along with ISO and TS certifications that govern manufacturing and quality standard at the Longmarch factory, all Longmarch tyres are certified to meet the legal Middle East standards. The Gulf Standard Organization (GSO) serves as the governing body for uniform grading of tyres based on the fuel economy and wet grip index. All Longmarch tyres sold in the region come with a GSO certification. Labels are placed on the tyres for easy identification and to meet specific legal requirements.

The Tyres for Your Fleet

Contact the Longmarch service team for personalised advice on the best tyres for your fleet. A dedicated representative will guide you through the options, based on the needs of your vehicles.